THE REBUILD PROCESS

INSPECTION/EVALUATION

This vital first step is a thorough process during which we develop a customized rebuild plan and cost estimate. The specific needs of your machine or power train are determined through a comprehensive evaluation, which includes fluid analysis, careful visual inspections and review of maintenance/S.O.S.™ analysis services. Cat Certified Power Train includes more than 200 tests and inspections.

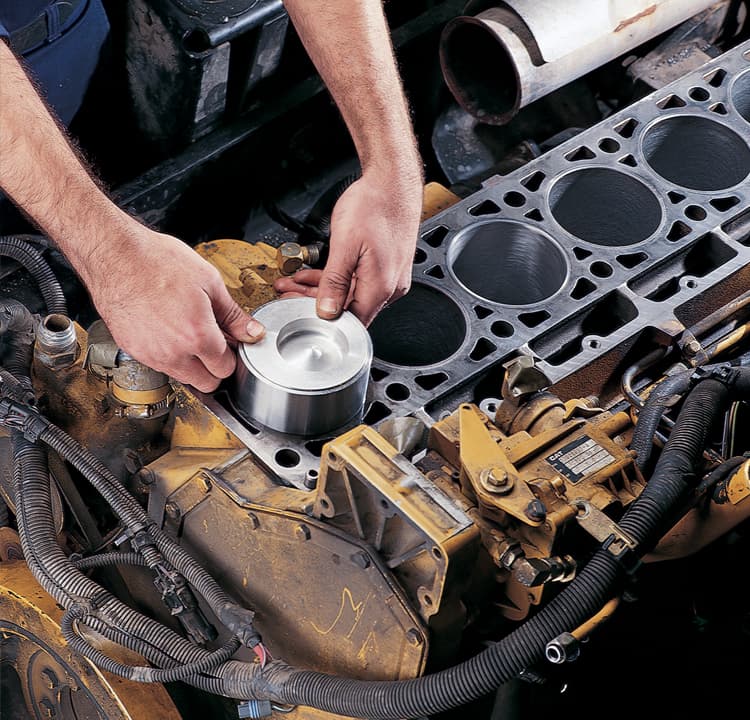

DISASSEMBLY

Once a CPT Rebuild plan is established, your Power Train will be completely disassembled. All hoses, belts, seals, gaskets, bearings, knobs, wiring, switches and gauges will be replace with new parts. Remaining parts will be inspected and measured against our strict re-usability guidelines. Those that do not meet our high standards will either be replaced with new or Cat Remain parts or reconditioned to meet guideline specs. Cat power train rebuilds include approximately 3,000 replacement parts.

ENGINEERING UPDATES

During reassembly, critical improvements that have been made to this machine model since original manufacturing will be incorporated into your power train.

POWER TRAIN TESTS

The engine, fuel systems, transmission, torque converter, differential, final drives and radiators are also disassembled, inspected, reconditioned and updated with new or qualified parts. Then, before re-installation, each component is thoroughly bench tested.

REASSEMBLY

All critical torques, clearances and pressure settings will be maintained and recorded during careful reassembly of your power train by our professional Technicians. Engine wire harnesses are always replaced.

PERFORMANCE TESTING

Quality control is integral to Certified Power Train Rebuilds. Rigorous testing is conducted at several stages. Tests routinely performed are: turbocharger boost, throttle response, stall speed rpm, transmission and steering clutch response. Contamination control procedures are followed to ensure the unit meets total system cleanliness of ISO 18/15. Instrument and operational testing are also conducted to ensure field performance levels match those in the shop.

REPAINTING

Your machine will perform like new – and look like new – after a complete paint job and application of new model identity graphics. Finally, a Cat Certified Power Train Rebuild decal will be issued.

CUSTOMER EVALUATION

The certified power train rebuild process is not considered complete until your operators are satisfied with the performance of the machine and the power train in its working environment.

CONTACT US TO GET STARTED

Ready to Start Your Rebuild?

We are ready to work with you! Yancey's Rebuild option allows you to tell us exactly what you would like to have rebuilt or repaired.

You can include any combination of components or systems to be rebuilt, from the hydraulic system to the final drive to a complete undercarriage rebuild. The choice is yours.

Fill out this form and one of our Yancey Bros. Co. Rebuild Specialist will contact you to discuss your machine rebuild needs.